EmbroideryStudio Printable Embroidery

Creativity Meets Cost Savings with Printable Embroidery

Wilcom pushes creative embroidery further than ever before. One of the most powerful and cost-effective techniques you can explore is EmbroideryStudio Printable Embroidery. All achievable through your existing all-in-one EMB file format.

In this article, we’ll showcase three practical ways to use this feature, demonstrated through our animal collection. Each approach reveals a unique balance between stitch and print — from mixed-media masterpieces to fully printed designs that still look embroidered.

Whether you’re a digitizer, fashion designer, or commercial decorator, these examples will inspire you to combine embroidery with print for maximum impact and efficiency.

3 VARIATIONS OF PRINTABLE EMBROIDERY

The results? Designs so striking, you’ll be left wondering:

Is it embroidery, or is it print?

Blend embroidery, printable embroidery, and vector graphics seamlessly with Wilcom EmbroideryStudio Printable Embroidery — unlocking creative possibilities while saving time and production costs.

1. Large Designs? Go Fully Printable

When working with large-scale or full-front designs, Printable Embroidery is a true game-changer.

Instead of stitching tens of thousands of stitches, a fully printable design delivers bold visual impact in a fraction of the time — especially on items like wet-weather jackets. Skip the puncture holes and heavy stitch density, and let high-resolution prints do the heavy lifting. You’ll achieve a striking result without compromising fabric integrity.

Take the Marble Grey T-shirt, for example. The stunning embroidery was created in Wilcom EmbroideryStudio by Sal Lucchese, featuring a striking Rhino design. The same artwork was then exported at 300 dpi and printed using Direct-To-Garment (DTG) technology - perfect for promotional items such as apparel or even mugs.Advantages:

Dramatically reduced stitch time and thread consumption

Lightweight, flexible finish ideal for apparel or when stitching isn’t suitable

Expands creative possibilities for fashion, sportswear, and promotional merchandise

Tip: Add just a few stitch highlights (like eyes or outlines) to create a realistic focal point and elevate the printed artwork.

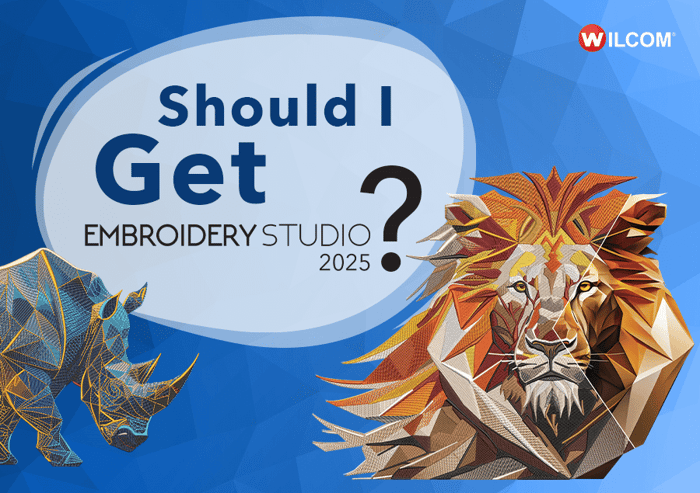

2. Mix Graphics with Printable Embroidery

This variation focuses on combining graphical elements with printable embroidery, using a simpler, more stylized approach.

Sometimes, less is more. Use graphics for details, textures, or accents, while printable embroidery fills large areas of color or complex detail. This balance creates an eye-catching design while still delivering a high-quality, professional finish.

For instance, in our lion samples, most of the texture is achieved through Printable Embroidery, with the graphics adding interest.

The lion design was printed in a single step using the Direct-To-Garment (DTG) method. Both the printable embroidery and vector graphics were exported directly from EmbroideryStudio.Advantages:

- Dramatically reduced stitch time and thread consumption

- Creates a modern look for branding and fashion applications

- Achieve the realism of print and the dimension of embroidery—without the bulk or complexity of traditional stitching.

FYI: The Wilcom logo is printable embroidery 🙂

Tip: Use Wilcom’s CorelDRAW integration to keep print and vector layers perfectly aligned within the same EMB file. This workflow ensures color precision and edge accuracy when printing.

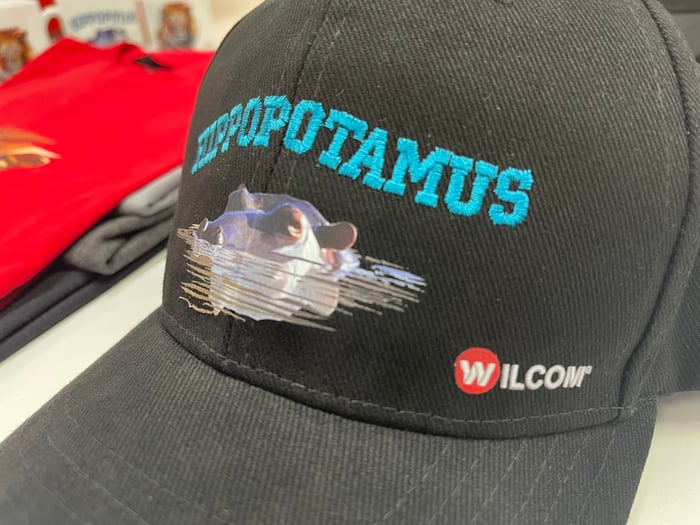

3. Mix Embroidery, Printable Embroidery, and Vector Graphics

This variation is perfect for multi-layered creative projects — where print, stitch, and vector artwork merge seamlessly. Create show-stopping designs by combining the best of all three.

In this technique, embroidery adds a tactile dimension, printable embroidery provides vibrant, detailed areas, and vector graphics enhance the overall composition. The combination delivers precision with personality, without the need for thousands of stitches.

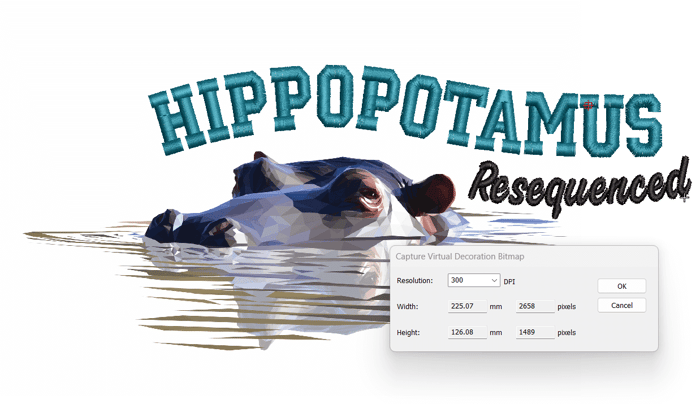

In this cap design, we use the hippo to showcase this technique.

- The animal’s body texture uses graphic detail to create a sense of photographic realism.

- Uses Wilcom’s world-class lettering to add the embroidered detail and blend the lines between print and embroidery

- Small details, such as the Wilcom logo, are added as printable embroidery, ensuring perfect alignment.

By layering embroidery with print and vector art, you can create designs that are visually rich but light to stitch, saving time and production cost without losing impact.

Tip: Add just a few stitch highlights (like outlines or lettering) to create a realistic focal point and elevate the printed artwork.

Why Printable Embroidery Matters

Printable Embroidery isn’t just a feature — it’s a bridge between digital art and traditional embroidery. You can easily use it in your own business cards, promotional materials, or marketing campaigns.

For embroidery businesses, it’s a way to offer high-impact, low-stitch designs — faster to produce, lighter to wear, and impossible to forget.

For commercial decorators, it means:

- Shorter production times for large or complex designs

- Consistent results across multiple garments

- A unique point of difference for clients seeking innovation

For designers, it’s a creative playground — a way to blend real texture, light, and color into a single, cohesive design.

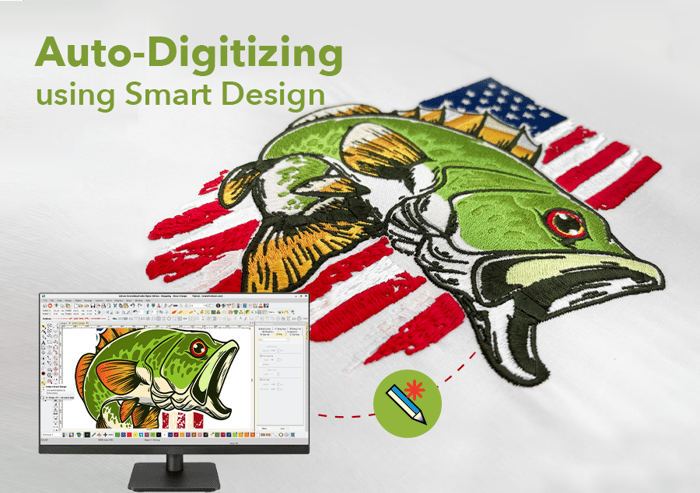

One Software, Endless Possibilities

Your favorite embroidery software, Wilcom EmbroideryStudio, makes it simple. Digitize your design as you normally would, then choose your output:

File → Capture Virtual Decoration Bitmap to generate a high-resolution print file — simply select your desired DPI

Start Blending Embroidery and Print Today

Printable Embroidery opens a new dimension in digitizing — where artistry meets production efficiency.

Bring your creativity to life with the best of both worlds. With EmbroideryStudio Printable Embroidery, your designs will be more versatile, more cost-effective, and more impactful than ever before.

So the next time you open your EmbroideryStudio ask yourself:

Will it be stitched, printed, or both?

Watch it in action

Ask about the world's

favorite embroidery software!

Contact us