Sustainable Embroidery: Eco-Friendly Tips

Sustainable Embroidery: Wilcom's Eco-Friendly Tips

How sustainable is your embroidery business?

As the industry evolves, so does the responsibility to reduce our environmental impact without compromising creativity or quality. From the materials we choose to how we digitize and produce designs, every decision can support a greener future.

One powerful step is switching to Madeira’s Green threads range, Polyneon Green and Sensa Green. Polyneon Green is made from 100% recycled post-consumer PET bottles. If you haven't tried Sensa Green, it's amazingly soft and has a matte finish. It's made from 100% Tencel lyocell, perfect for high-end fashion, baby wear, and hand embroidery.

Both offer exceptional quality while supporting more eco-conscious production. And the best part? You can easily access these thread charts within EmbroideryStudio—plus, we’ll show you how to create your own custom chart later in this blog.

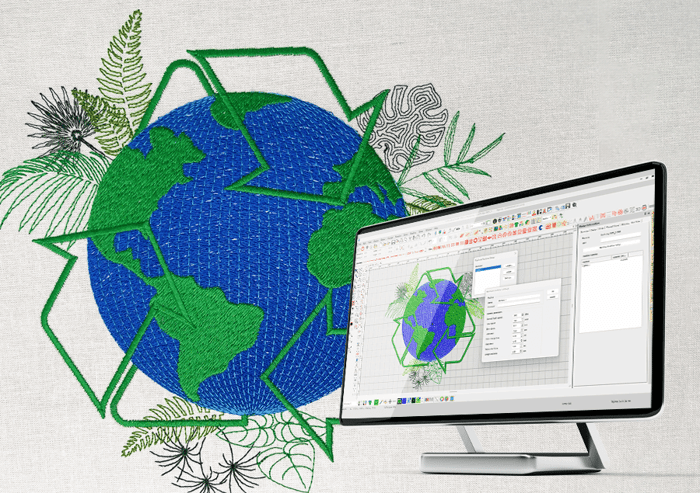

Smart Embroidery Starts With Your Software

You might be surprised by how much you can do within Wilcom’s EmbroideryStudio software to support eco-friendly practices.

Sustainability goes beyond thread choices—it includes smarter digitizing, better machine planning, and tools designed to reduce waste and increase efficiency.

Optimize for Efficiency and Reduce Waste

To minimize thread waste, start by using the Stitch Player to preview how your design will run on the embroidery machine. Then, take advantage of EmbroideryStudio’s smart features to further optimize your design.

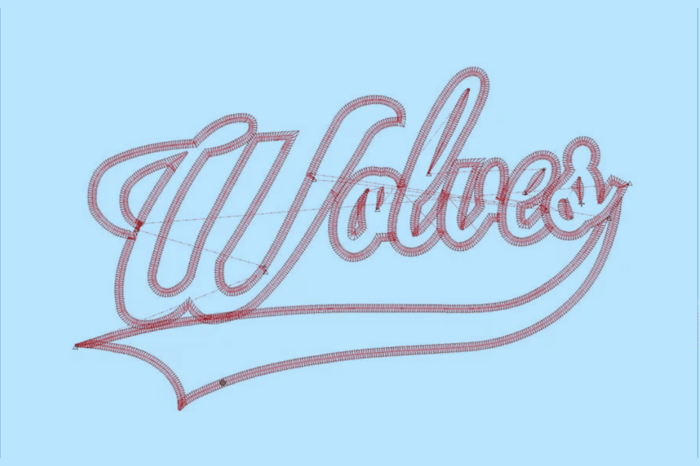

Use Branching:

This tool efficiently connects objects, reducing trims and machine stops.

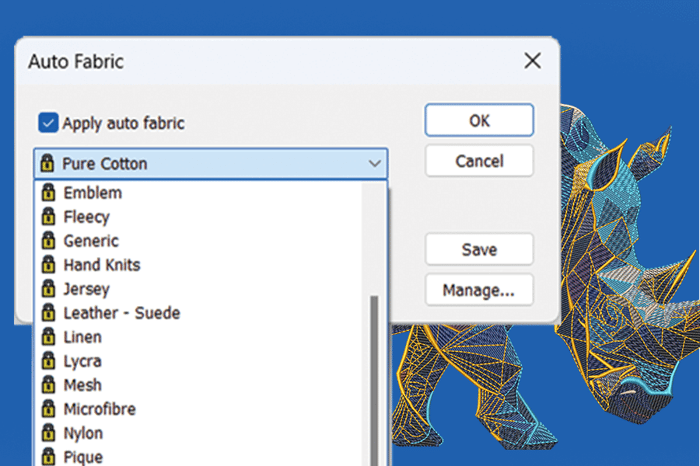

Fabric Assist:

Automatically adjust all the stitch settings to suit your chosen fabric, saving time and materials.

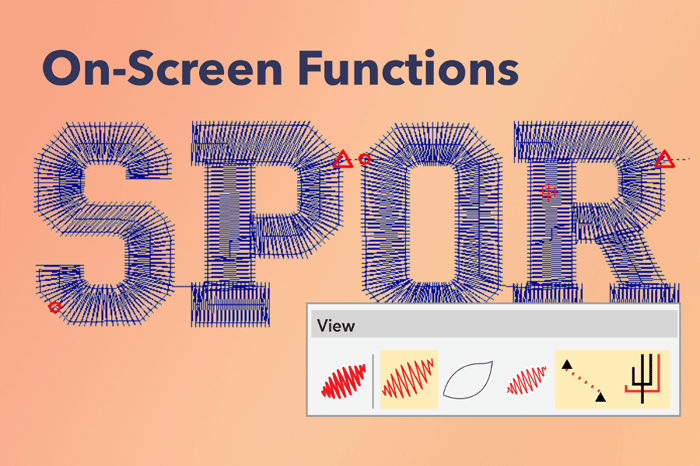

Visualize Machine Functions:

Visualize Machine Functions:Quickly identify and eliminate unnecessary trims with EmbroideryStudio’s new visual tools. Multiple trims can add up fast, so reducing them saves more than just thread—it improves overall efficiency with every run.

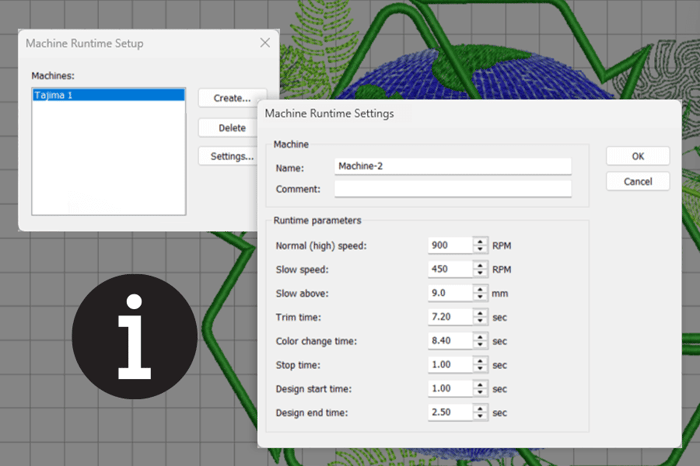

Run Time Tab:

To know how long a design will run on your machine, open the Design Information docker and click the Run Time tab. You can use Wilcom's default settings or change them to suit your specific embroidery machine.

Plan Production More Efficiently by Understanding Run Time

Knowing how long a design will take to run helps you schedule jobs more effectively. Below are some average figures to guide your planning:

- Logo Stitch Count: 5,000 - 8000

- Machine Speed: 750 RPM

- Color Changes (6 - 9 seconds each)

- Trims (4 seconds each)

Quick Formula: Estimated Runtime = Stitch Count ÷ RPM

The good news? This calculation is already available in your .EMB file under the Design Information docker.

Take a moment to review all the details stored with your embroidery file.

Other Simple Sustainable Practices

Organize Your Threads by Color

Know what you have to avoid overordering. You can even save custom thread collections—including threads from different brands—right within EmbroideryStudio.

We’ll show you just how easy it is:

How to Create Your Own Custom Threads Chart

Go Digital:

Switch from paper to digital Approval Sheets, Production Worksheets, and receipts to reduce paper waste.

Save Backing and Stabilizer

Keep off-cuts for sampling and test runs instead of throwing them away.

Repurpose Mistakes

Don’t bin old or flawed pieces—reuse them for embroidery testing or training.

Celebrate & Share Your Commitment

Let your customers know about your eco-conscious choices! Share your sustainable embroidery efforts on social media—highlight how you use EmbroideryStudio’s productivity features and incorporate Madeira’s Green thread range into your designs.

These small changes can make a big impact. Your embroidery business can be part of a global movement toward a healthier, more sustainable planet. Sustainable embroidery is not just a trend—it’s the future!

Let’s stitch a greener tomorrow—one thread at a time.

Ask about the world's

favorite embroidery software!

Contact us